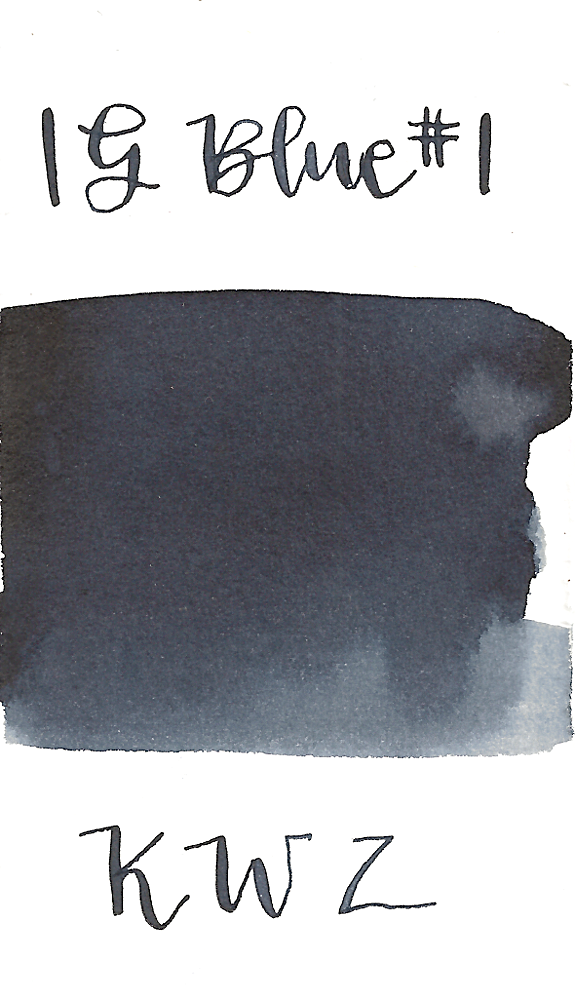

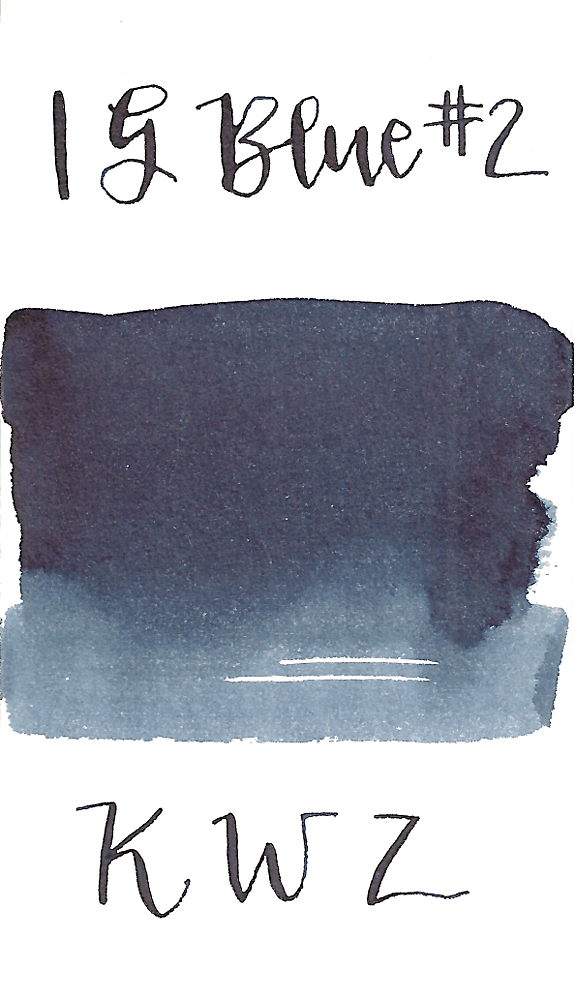

The recipe KWZ (pronounced Ka Veh Zeh) Ink uses to produce Iron Gall was developed in the first half of 2013. Konrad constantly improves his inks and systematically introduces minor changes to their recipe, but the basics of it has not changed significantly. There have been no cases of corrosion or blockage due to precipitation in fountain pens which were inked with KWZ Iron Gall inks for their standard use.

PLEASE NOTE: leaving Iron Gall ink in an unused pen for a very long period of time could cause corrosion to occur in pens with stainless steel nibs.

Nibs made of gold, titanium, palladium, platinum, silver, etc. are generally resistant to corrosion and it is not possible under any circumstances to have corrosion by the Iron Gall inks or any other type of ink.

Iron Gall inks are waterproof and require compliance with a number of recommendations. Following these guidelines will protect and prevent any problems that might occur during the use of Iron Gall inks in fountain pens.

Iron Gall inks are a specific group of inks – brief description of the processes that take place in the ink goes beyond this short tutorial. User should be aware that well stored Iron Gall ink is a true solution, there is no solid residue suspended in the ink. Only after application of Iron Gall ink on a substrate (ideally paper) and evaporation of most of the water; reactions occur which gives a water-insoluble complex of iron with an intense dark color.

The same reactions which are responsible for darkening and formation of water insoluble complexes of iron are also unfortunately possible in the interior of a fountain pen. This can happen if a fountain pen is left unused for long time or if a fountain pen has the tendency to quickly dry out. Cleaning dried Iron Gall ink is not especially difficult, but it requires a lot of time and patience (especially if you do not want to disassemble the pen). Iron Gall inks should be used in fountain pens that are used regularly.

Do not use Iron Gall inks in pens that tend dry out when you leave them for relatively short period of time. It is normal that if a fountain pen is left for a week or two, the beginning of writing may require a bit of pressure. However, if the pen nib is dry after a day or two without use, that pen should not be used with Iron Gall inks.

If Iron Gall ink stored in the tightly twisted bottle begins to form deposits of solid on the walls and bottom of bottle then it should not be used in fountain pens. Spontaneous formation of sludge in Iron Gall inks is caused by improper handling, contamination, or by inappropriate proportions of ingredients used in the ink.

Before inking a fountain pen with Iron Gall ink; it should be thoroughly washed – especially if other types of waterproof inks were used in this pen. Similarly, if you change the ink in your fountain pen from Iron Gall ink to a different type of waterproof ink you should wash it thoroughly. Iron Gall inks can interact with certain inks, which will result in the formation of difficult to remove sediment in fountain pens.

If Iron Gall ink is left in unused fountain pen for long time, and it partially dries out, it should not be returned to the inkwell with ink – in this case, pen should be rinsed with water like before changing the ink. Returning old ink to the bottle will have a negative impact on the stability of such ink and may cause the formation of sediment in the inkwell.

KWZ produced Iron Gall inks will not cause corrosion with normal use in fountain pens with nib made of stainless steel or gold. Some nibs made of ordinary steel are protected against corrosion, for example by passivation layer (usually chromium). With this type of nib, it is possible for corrosion, especially if the passivation layer is mechanically damaged. Most species of stainless steels will interact very little with a magnetic field – if the nib is attracted by a magnet, then with a high degree of certainty it can be concluded that it was not made of stainless steel or the steel was not properly processed.

Iron Gall inks should be stored in a cool and dark place to protect them from the negative effects of light on their stability.

Iron Gall inks should not be diluted with water from the tap – the water is rich in various salts and contains trace amounts of the compounds used for the decontamination of water (such as ozone, chlorine, etc.), those compounds will have negative effect on stability of ink. If you want to dilute Iron Gall ink, distilled, demineralized water or boiled water should be used.

Filters

Filters